Transitioning to low-embodied carbon and circular sustainable solutions in technical installations in buildings

Change is coming – Are you ready? The building industry has to contribute to reaching global climate targets. New business ways are needed to minimize embodied carbon in technical installations, and knowledge is required to apply it to the HVAC industry. There is a need to create circular solutions for customer needs, circularity measurement practices, and maintain the value of products after their first use cycle, i.e. dismantling and reversed logistics, product life extension, circular sourcing and procurement. Also, linking embodied and operational carbon together with circularity in building installations will give a clear outlook for future sustainable strategies.

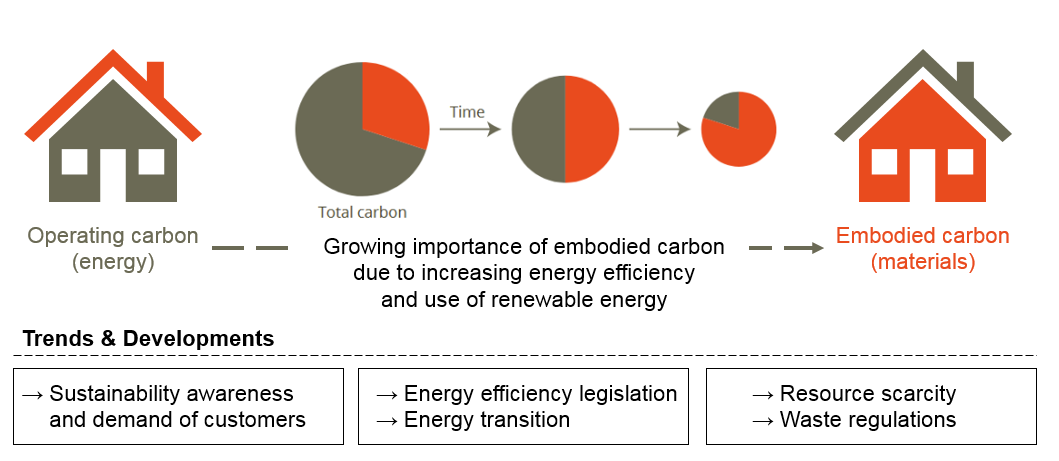

Shifting focus from operational to embodied carbon.

The building's product lifecycle (LCA) can be divided into different modules: material/product stage, construction-process stage, use stage, and end-of-life stage. For a long time, the traditional focus was on energy consumption in the use stage due to its link to carbon emissions (operational carbon) and costs. However, we are now seeing a growing and future focus on the other stages, especially on the materials and products stages (embodied carbon) in the lifecycle assessment (LCA).

Operational carbon comes from the energy and water used in the use stage. When we look at trends and developments, sustainability awareness and customer demand are essential, as are energy efficiency legislation, energy transition, resource scarcity, and waste regulations. Then, we see that the use stage will become more renewable and fossil-free. This confirms that the importance of embodied carbon, especially in materials/production, will increase (since the carbon footprint in the use stage becomes lower).

A fundamental difference exists between the two economic models – linear and circular. The linear economy follows the 'take-make-waste' conventional business model (sometimes considering only recycling or reuse). However, the circular economy follows the multiple Rs (also so-called RE tactics) approach of 'refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover', completely removing waste from the equation. However, the suitability of the various approaches can vary between products, companies and projects. Finally, it can be stated that most of the Rs approaches have a significantly lower embodied carbon footprint. The transition from linear to circular economy is a necessity for the future.

A property owner's perspective on circularity.

Legislation and legislators support the transition and increasing demands on the building industry through EU taxonomy, especially climate transparent reporting and the corporate sustainability reporting directive (CSRD) in the whole stakeholder chain. Financial steering regulations in markets are becoming more relevant for property investors and owners (green funding, building certifications and advantageous financing).

Going circular also helps lower the cost for investors and property owners through using fewer materials, optimizing supply chains, and lowering energy use - which inevitably correlates with environmental impact. Circularity has a substantial role to play, as we see that the circular or sustainable mindset can reduce operational energy by 10% and even more in the future. Several studies also indicate the influence on the rent market (an increase of 5-15 % rents for 'greener' / certified buildings), thus providing an attractive and lower investment risk. Financial value is also a great driver for the property market (when appraisal of building valuation greener building with lower risk and therefore higher property values) and beneficial condition for loans or other financing methods like bonds when the building is sustainable.

Managing embodied carbon in practice.

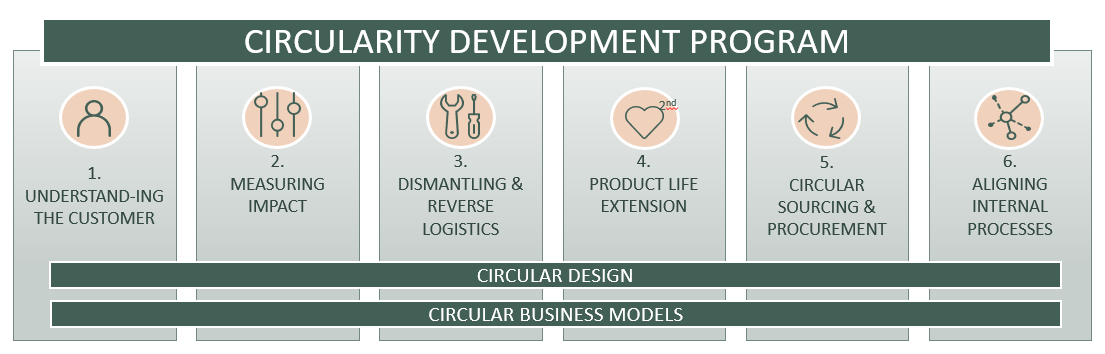

Finding circular solutions for buildings’ technical equipment will significantly impact advancing decarbonization in the building industry. The study conducted by Ramboll shows that when considering a building's whole lifecycle, technical equipment is the third largest emission source after energy and main construction materials. The circularity development program, an example from Vasakronan in Sweden, showcases circular business models, including circular design, and the following key learnings.

Understanding the customer: early communication between manufacturers and other value chain members is essential for creating circular solutions.

- Reviewing the customer expectations for a product provides a base for product development in the company.

- Instead of focusing on a single customer need, the plan must consider the entire chain (customer to customer, supplier to supplier).

- The construction sector's decision-making must be solid, emphasizing the need for new collaborative procedures and early communication between manufacturers and other value chain members.

Measuring impact: the lack of standard measurement frameworks and available circularity data requires new ways of sharing information throughout the value chain.

- Measuring sustainable practices and their adaptability for companies can help assess emission reduction and circularity potentials and define priorities for circularity development opportunities.

- Measuring circularity is complex, mainly due to the lack of standard measurement, frameworks, common language, and circular data availability.

- Therefore, new ways of sharing information throughout the whole value chain are mandatory.

Dismantling & reverse logistics: entirely new processes, roles and business logic are required.

- Focusing on how to maintain the value of products after their first use in their lifecycle and how to capture the value from dismantling and logistics.

- Shifting from a linear business model to reverse logic requires the creation of entirely new processes that do not exist yet in the linear model.

- In the circular loop, many stakeholders must adapt entirely new roles, which impacts cost and business logic.

Product life extension: Re-tactics ensure the longer lifetime of existing products, and circular design plays a pivotal role in allowing circularity in the future.

- Extending the lifetime of products by opening circular economy tactics, including reuse, refurbish, remanufacture, revitalise, resell, and circular design.

- Companies must conduct extensive studies to create lifetime extension plans for chosen products.

- Circular design is pivotal in extending the lifetime of products to allow circularity in the future. At the same time, the value of existing products on the market must be addressed, thus extending their lifetime as well as possible. Thus, we focus on two strategies - circularity design for new products and tactics to extend the lifespan of existing products.

Circular sourcing & procurement: sourcing is a key function for operationalizing and scaling many circular initiatives in companies.

- Circularity transformation by sourcing circular inputs and considering circularity in procurement practises.

- Explore landscape views of future material flows and benchmark leading circular sourcing practices, including circular procurement development in construction projects.

- Driving circular procurement and sustainable sourcing practises requires a collaborative approach across the value chain and creates new types of relationships; for example, customers might now become suppliers of new products.

- Sourcing is a key function for operationalizing and scaling the company's circular initiatives.

Aligning internal processes: commitment is best achieved when top-down and bottom-up strategies are integrated, and there is organization-wide cohesion for action.

- The companies must support scaling circularity internally by identifying internal processes, practises and competencies that either hinder or support the transition to a circular economy.

- Scaling circularity internally demands a shift in organizational culture, processes, and capabilities, requiring extensive education and training, collaborations across functions and value chains, and a long-term vision for circularity.

- Commitment to change throughout the organisation is best achieved by executing top-down and bottom-up strategies.

Conclusion

We can see the link between technical installation in buildings and circularity through various approaches.

We shift from operational to embodied carbon by replacing more fossil fuel energy sources with renewable resources. The challenge lies in managing the tradeoffs between traditional linear business and more circular sustainable approaches. Further competence and knowledge development based on the different specifications of countries (various legislation and regulations), industry (process implementation), companies (business potential) and products (including customers' demands) are also needed.

Driving the changes for higher levels of sustainability and circularity.

Recent experience and perspectives show that customers' and tenants' demand clearly indicate their support of high sustainability and circularity. There are many financial incentives behind the sustainability motivators for property owners and investors, including green loans and funding. The value of technical installations and materials in buildings lies in implementing sustainable changes from larger-scale solutions by preserving the already created value instead of destroying it and wasting the resources for a new product.

Managing embodied carbon in practice.

The main motivation for suppliers is to offer the complete product that the customer requires. The supplier, as a responsible stakeholder, must be economically aware and have a prosperous potential, but also must apply environmental and social aspects.So, circularity ticks a lot of boxes because it is promising and will be in great demand now and in the future.

Reference

This text is based on the Swegon Air Academy webinar: Change is coming – Are you ready? The experts are Mirko Sauvan, Sustainability Manager Corporate Functions at Swegon Group, Louna Laurila, Business Development Manager at Combient Pure and Mikael Börjesson, Competence and Sustainability Director at Swegon Group, and with Åsa Norén-Lundh, Indoor Environmental Competence Manager at Swegon Group, as the moderator of the webinar.